Understanding Epoxy Prepregs

What are Epoxy Prepregs?

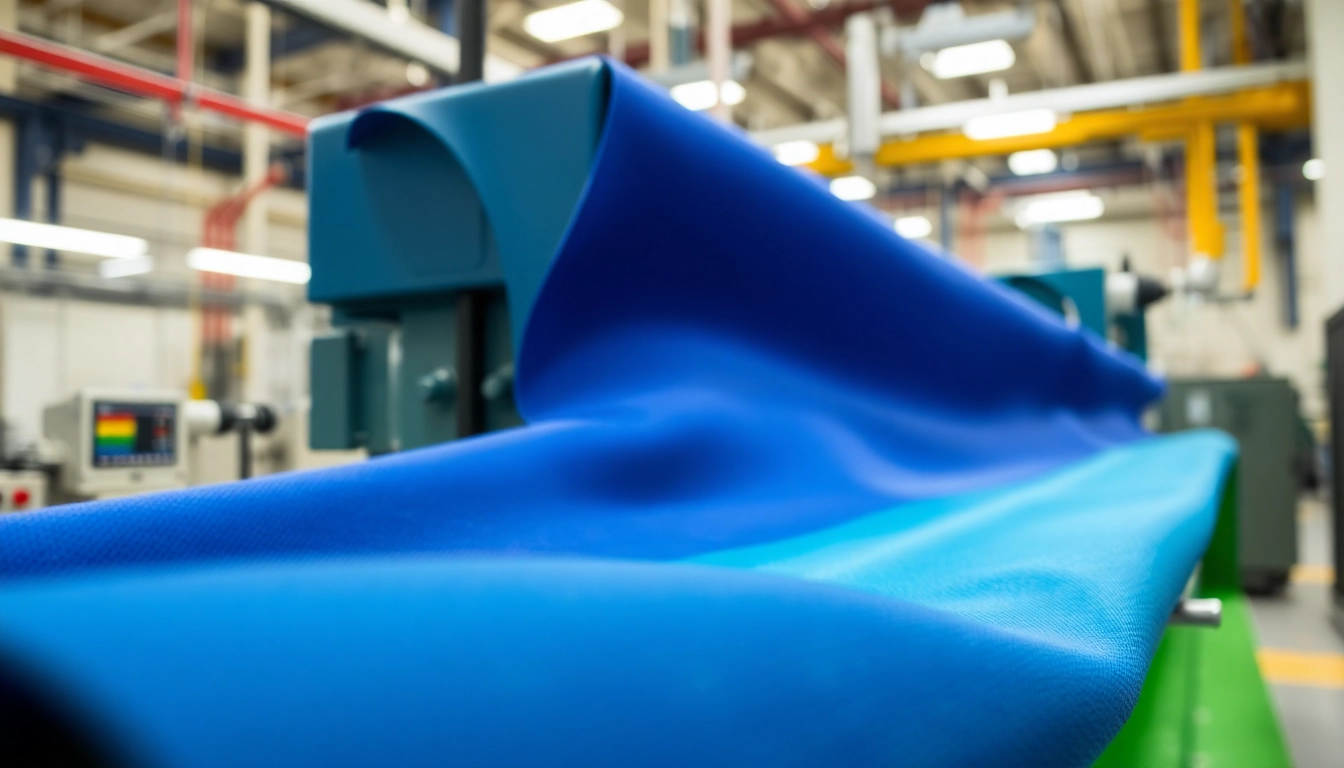

Epoxy prepregs, short for pre-impregnated materials, represent a groundbreaking advancement in composite manufacturing. These materials consist of reinforcing fibers that are coated with a thermosetting resin system, typically epoxy, before any manufacturing process is undertaken. This preparation allows the fibers to be saturated with resin, which provides significant advantages in terms of strength, durability, and consistency. The use of epoxy prepregs simplifies the composite creation process, leading to high-performance outcomes across various industries.

Components of Epoxy Prepregs

The main components of epoxy prepregs include reinforcement fibers and the epoxy resin system. The reinforcement fibers can be made from materials such as carbon fiber, fiberglass, or aramid, depending on the desired strength and weight characteristics. These fibers provide the structural integrity while allowing for lightweight applications.

The epoxy resin system is crucial in determining the final properties of the composite material. The resin must be chosen based on factors including cure temperature, viscosity, and mechanical properties. The ratio of resin to fiber is also vital; an optimum balance must be achieved to ensure that the resulting composite has enhanced performance, stability, and durability.

Benefits of Using Epoxy Prepregs

Utilizing epoxy prepregs offers multiple significant benefits:

- Consistency: Since the resin is pre-impregnated, there is a uniform distribution of resin and fibers, ensuring consistent quality in the final product.

- Strength-to-Weight Ratio: Epoxy prepregs provide excellent strength without adding excessive weight, making them ideal for aerospace and automotive applications.

- Reduced Processing Time: The ease of handling and molding epoxy prepregs can considerably shorten production timelines, enhancing overall efficiency.

- Less Waste: The precision in resin application minimizes excess material, leading to reduced waste during manufacturing.

- Excellent Adhesion: Epoxy provides superior adhesion properties, which result in stronger bonds in layered constructions.

Applications of Epoxy Prepregs

Aerospace Industry Utilization

The aerospace industry is one of the leading sectors in adopting epoxy prepregs due to their lightweight characteristics and high strength. Components subjected to high stress, such as wing structures and fuselage parts, greatly benefit from the properties of epoxy prepregs. These materials contribute to fuel efficiency by reducing overall weight while maintaining structural integrity in aircraft.

Moreover, the reliability of epoxy prepregs under varying temperature conditions makes them suitable for use in high-performance jet and spacecraft applications. The rigorous testing and certification processes that are integral to aerospace manufacturing frequently employ epoxy prepregs to ensure compliance with strict industry standards.

Automotive Manufacturing Applications

In the automotive sector, the trend towards lightweight composite materials has spurred an increased use of epoxy prepregs. From body panels to reinforcing structures, these materials contribute to improved fuel efficiency and reduced emissions in vehicles. Epoxy prepregs can be molded into complex shapes, allowing for design flexibility that is essential for modern vehicle manufacturing.

As automotive designs continue to incorporate advanced technologies—such as electric vehicles—epoxy prepregs are critical for battery enclosures and structural components, offering both protection and insulation. The high performance of these materials in extreme conditions ensures durability and safety in automotive applications.

Sports Equipment Advancements

The sports industry has recognized the potential of epoxy prepregs for creating high-performance sports equipment. From bicycles to golf clubs and helmets, these materials enhance performance by providing optimal strength and weight distribution. Epoxy prepregs allow for the manufacturing of tailored sporting goods that are not only lightweight but also capable of withstanding high levels of impact and stress.

Innovations such as customizable stiffness profiles and enhanced aesthetic options are made possible by the versatility of epoxy prepregs. As sporting technology advances, the integration of epoxy prepregs will likely grow, providing athletes with superior equipment that fosters improved performance and safety.

Manufacturing Processes Involving Epoxy Prepregs

Prepreg Layup Techniques

The layup process is critical in the manufacturing of composites using epoxy prepregs. Prepreg layup involves placing layers of prepreg materials in a mold according to a predetermined sequence. The fibers are laid out in specific orientations to achieve desired mechanical properties in the final product.

Common techniques include manual layup, automated tape laying, and filament winding. Each method has its own set of advantages, such as precision, speed, and complexity of shapes that can be achieved. The choice of layup technique depends on the specific application requirements and the volume of production.

Curing Methods Explained

Curing is the process through which the epoxy resin hardens, transforming the prepreg material into a solid composite. There are various curing methods available:

- Oven Curing: The most traditional method, wherein the assembled layers are placed in a controlled oven environment to facilitate curing. This method ensures uniform hardening but requires careful handling to prevent overheating.

- Autoclave Curing: This method employs high pressure and temperature for curing, which results in superior fiber-to-resin ratios and improved material properties. Autoclave curing is often used in critical aerospace structures.

- Room Temperature Curing: Some epoxy prepregs can cure at room temperature, making them easier to handle and reducing energy consumption during the manufacturing process. However, this method may require longer curing times and can affect material properties.

Quality Control in Prepreg Production

Quality control is essential in the production of epoxy prepregs to ensure that the final composite material meets stringent industry standards. This involves monitoring the resin viscosity, fiber content, and thickness of the prepreg layers. Testing methods such as mechanical property evaluations, thermal analysis, and chemical composition assessments ensure that any potential defects are identified early in the manufacturing process.

Maintaining consistent quality helps prevent costly failures in the composite’s end-use applications, making quality control a critical investment in the production line.

Challenges in Working with Epoxy Prepregs

Handling and Storage Considerations

Epoxy prepregs require careful handling and storage to maintain their efficacy. They are typically delivered in a refrigerated or frozen state, necessitating cold storage solutions. If not appropriately stored, the resin can cure prematurely, rendering the prepreg unusable. Additionally, the prepregs must be used within a specific outlife window once thawed, emphasizing the importance of efficient inventory management.

Moreover, handling these materials requires attention to detail to prevent contamination, which could negatively impact the bonding process and overall product performance.

Material Properties and Limitations

Despite their many advantages, epoxy prepregs do come with certain limitations. While they offer robust mechanical properties, their performance can be affected by factors such as temperature fluctuation and exposure to moisture. It is essential to consider these factors during application to ensure that materials are appropriate for the end-use environment.

Additionally, the curing process can be sensitive to time and temperature, requiring precise control throughout the manufacturing process. Failure to adhere to recommended parameters can lead to incomplete curing, impacting the properties of the final composite.

Cost Factors and Budgeting

The cost of using epoxy prepregs can be higher than traditional composite manufacturing methods. The materials themselves, alongside specialized equipment for curing and handling, contribute to initial capital investment. However, considering the long-term benefits—such as reduced waste and enhanced durability—epoxy prepregs can lead to cost savings in production as well as in the lifecycle management of the final products.

Budgeting for projects that involve epoxy prepregs should include considerations for tooling, storage, and quality control measures to offset any potential additional costs associated with this advanced manufacturing process.

Future Trends in Epoxy Prepregs

Innovations in Material Science

The future of epoxy prepregs is poised for continual innovation. Research and development efforts are dedicated to enhancing the material properties, including improved thermal resistance and higher damage tolerance. Emerging composites that incorporate nanomaterials or hybrid systems promise to further increase strength while maintaining lightweight characteristics.

Moreover, advancements in automated manufacturing techniques will revolutionize the fabrication of epoxy prepregs, making production more efficient and cost-effective. The integration of smart materials that can adapt to changing environmental conditions is also on the horizon.

Environmental Considerations

As industries shift toward sustainable practices, the development of eco-friendly epoxy prepregs is increasingly important. Innovations aimed at reducing the environmental footprint of composite production include the use of bio-based resins and recyclable fibers. As regulations tighten around sustainability, manufacturers will need to adapt their processes and materials to meet these new standards without sacrificing performance.

Market Outlook for Epoxy Prepregs

The market for epoxy prepregs is expected to grow significantly due to rising demand in various industries, including aerospace, automotive, and sports equipment. As advancements in composites continue to emerge, companies utilizing epoxy prepregs will find new opportunities for innovation and expansion.

Additionally, the push towards lightweight and high-performance materials will drive investment in research and development, ensuring that epoxy prepregs remain at the forefront of composite technology.